Your benefits at one glance

Our mechanical pipe couplings are your key to streamline your pipe connection projects while optimizing costs. Scroll down to uncover how our innovative features can elevate your success.

Optimize efficiency

System design: No need for prior pipe alignment or complex pipe end treatments.

→ Faster and more straightforward system planning.

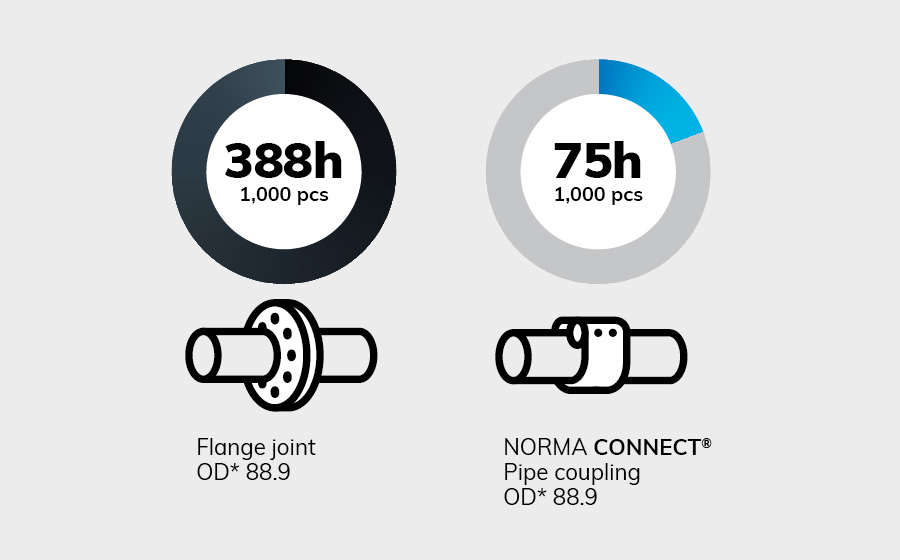

Installation: No welding required.

→ Up to 80%-time savings compared to flange connections.

→ Learn how to relieve your welders in a clever way

Maintenance: Easy disassembly and reassembly with only two screws.

→ Convenient and efficient pipe maintenance.

Maximize cost savings

System design: One versatile solution for various pipe materials and combinations, simplifying procurement and reducing inventory costs.

→ Cost-effective system design.

Installation: Avoid welding expenses and the need for specialists and expensive tools.

→ Budget-friendly installation

Maintenance: No exchange of seals etc. required

→ Our pipe couplings do usually not require any maintenance.

Experience peace of mind

System Design: Our pipe couplings have proven themselves in countless applications over decades.

→ A proven and tested joining solution.

Installation: Designed for easy installation, reducing the risk of injuries. No specialized training required.

→ Safe and straightforward installation

Maintenance: Our certified products adhere to the highest quality standards, ensuring long-term reliability and safety. Learn more about certifications (Link)

→ No regular maintenance requirements

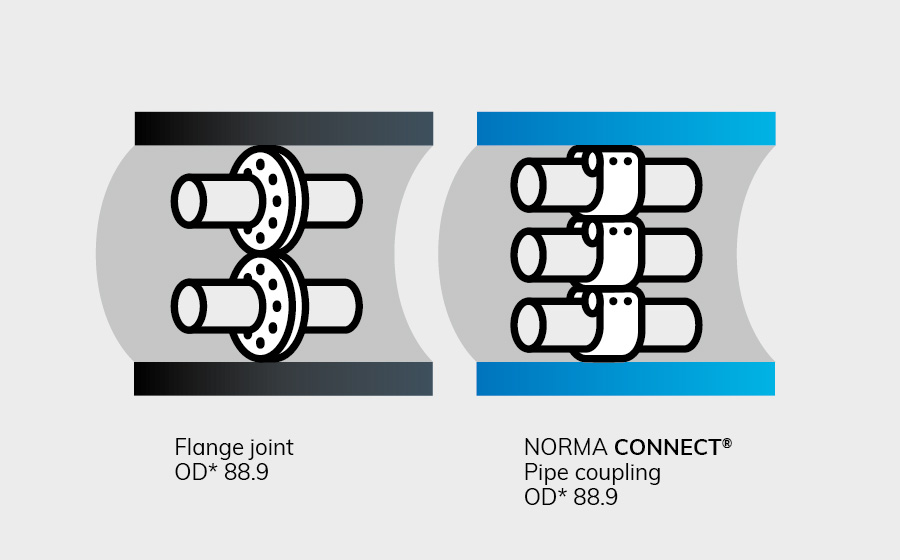

Save space

System design: Requires considerably less enclosed space in your system's design.

→ Enhances layout and design flexibility compared to conventional joining methods like flanges

Installation: No big equipment or complex tools required

→ Can be installed in areas which are hard to access

Maintenance: Easy access to the screws

→ Space limitations do not impede an easy maintenance

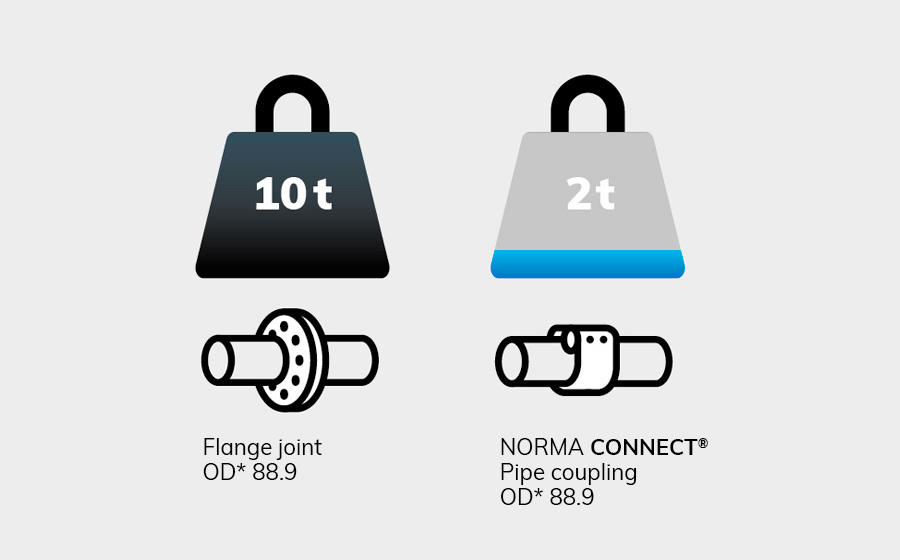

Ensure weight efficiency

System design: Achieve up to 70% weight reduction compared to flange connections. Significant impact on overall system weight and transportation costs.

→ Lightweight and efficient system design

Installation: Lightweight couplings can be handled easily by a single person.

→ Effortless installation with reduced labor requirements

Gain flexibility

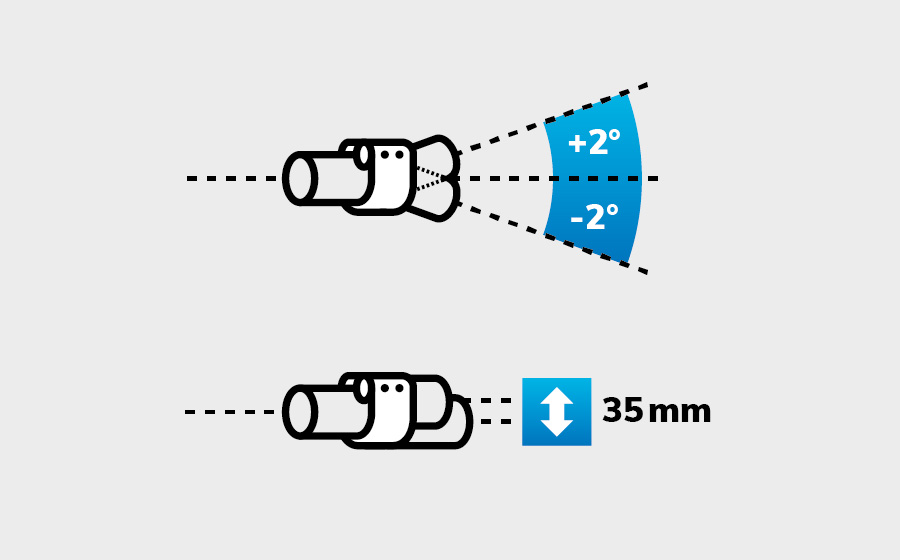

Installation: Compensates for pipe tolerances like gaps, axial movements, misalignment, and angular deflection during installation

→ Adapts to challenging installation conditions with ease.

Maintenance: Detachable connections make system expansion and modifications easy.

→ Easily expand and modify your systems.

A True Welding Alternative

Expertly designed to connect all plain-ended pipes metal or plastic. These couplings serve a wide range of purposes, facilitating the transport of both liquid and gaseous media. From essential applications such as process water and compressed air to critical functions like lubrication lines and energy-supply conduits, including steam and condensation lines, process lines, and heat and cooling lines.