How to select the right pipe coupling

At NORMA, you’ll find a wide of range of pipe connectors and couplings for pipes perfectly adapted for numerous real-world conditions. For installation or repair of different pipe materials under various temperatures, pressures, and chemical or mechanical conditions, NORMA has precision couplings that install quickly, safely and efficiently.

In this article you will learn:

- How to choose the right type of pipe coupling for your application

- Which parameters you need to know to select the right pipe coupling size and material

Let's find the best connection together

We'll help you connect the right pipe coupling

It all begins with your job. You bring project knowledge; NORMA brings the appropriate types of couplings. Start with the application and its conditions: installation or repair? Axially restrained or unrestrained? Then consider the pipe materials – metal or plastic – that must be coupled. Determine the true outside diameter (versus the nominal diameter) to arrive at the right size. Finally, choose the coupling materials appropriate for the gases, fluids, or solids being managed under the temperatures and pressures you expect, and the engineering and regulatory standards that apply to your site.

On this page, you’ll find the resources you need to simplify the search for metal pipe connectors, plastic pipe connectors, and mechanical couplings. By following four simple steps and using the appropriate links to our catalog, datasheets, and manuals, you’ll arrive at the pipe coupling type that best balances ease of application, durability, and economy for your specific needs.

Follow these four simple steps

Determine the Application

Are you connecting two pipes or repairing a damaged connection?

Identify the Pipe Material(s)

What are you connecting: metal + metal, plastic + plastic, metal + plastic?

Find out the

Correct Size

Have you measured the true OD (outside diameter)?

Choose the Best Coupling Material(s)

What’s the right material: W2, W4, W5; EPDM, NBR, FKM?

Application

New connection or repair?

Consider your project. NORMA provides two fundamental types of mechanical couplings for CONNECTING two pipes together or REPAIRING a damaged connection.

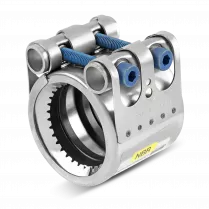

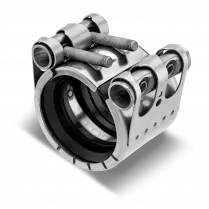

- When you want to CONNECT two pipes:

- GRIP: Provides a leak-free connection without pipe damage in axially restrained conditions.

- FLEX: Flexible pipe couplings that allow for axial and expansion movement without leakage.

- COMBI GRIP: Universal couplings for different pipe material types (e.g., metal + plastic).

- PLAST GRIP: Plastic pipe couplings that connect plastic + plastic pipe types.

- When you need to REPAIR damaged pipe:*

- REP E non-restraint repair coupling: Enables fast and reliable repairs in environments where welding is impractical or unsafe.

* Note: If you choose the REP E coupling, go directly to Step 3 as our REP E coupling can be used with both metal and plastic.

Pipe Material(s)

Which pipe materials are you connecting?

You need to find the right connector/coupling for both the pipe materials at hand (metal, plastic) and the installation context: axial restraint versus non-axial restraint.

Please keep in mind that NORMA GRIP connectors allow for misalignment of up to 1% of the pipes’ outside diameter (OD) and for angular deflection of up to 4% (2% per side). To safely allow greater movement, look to the NORMA FLEX line of couplings.

Note, too, that FLEX couplings can be used within a pipeline to accommodate thermal expansion without installing an expansion joint. Please refer to our technical manuals for further details.

Connect metal pipe + metal pipe:

- Axial restraint coupling: GRIP type

- Non-axial restraint coupling: FLEX type

Connect plastic pipe + plastic pipe:

- Axial restraint coupling: PLAST GRIP type

- Non-axial restraint coupling: FLEX type

Connect metal pipe + plastic pipe:

- Axial restraint coupling: COMBI GRIP type

- Non-axial restraint coupling: FLEX type

The Right Size

What’s the real outside diameter (OD)?

For correct pipe couplings dimensions, you need to know the true outside diameter of the pipe (OD), not merely the nominal diameter used to identify the pipe size. Before requesting a quote or placing an order, determine the real outside diameter (OD).

NORMA makes sizing easy. You can find the necessary product information in our Infrastructure catalog, our technical manual, or by downloading the appropriate datasheet. In the reference documents, select the correct coupling type and look for the corresponding clamping range.

Do not neglect system pressure requirements; be sure to check the datasheet or catalog for the appropriate pressure specifications. In addition, our tech specifications include important information about the weight of the coupling, the dimensions, and the correct tightening torque.

Coupling Material(s)

Which materials will work best?

Depending on the coupling type and size, you may have the choice between several connector materials:

- W2: Housing made of stainless steel, combined with unalloyed galvanized steel components; for building interiors without critical hygiene or corrosion concerns.

- W4: Housing made of AISI 430 stainless steel, closure made of 316Ti; materials for installations with greater concern for hygiene and/or corrosion.

- W5: High-grade AISI 316Ti stainless steel for in-ground or industrial applications.

For more precise information about NORMA connector materials, please refer to page 30 in our Infrastructure Catalog.

In addition, you may also have choices among available sealing materials:

- EPDM rubber gaskets for water, air and solids

- NBR nitrolic rubber for gases, oils and fuels

- FKM: fluid polymeric rubber for oil and fuel applications and saturated steam systems (cleaning, disinfection and industrial) that must resist high heat and pressure

You may find the respective temperature ranges in our datasheets, manuals or catalog.

If you have further questions regarding the chemical resistance of our sealing materials, please contact our Product Line Manager.

Finally: Always make sure you are compliant with your local and national regulations and laws.